Most Popular Products

|

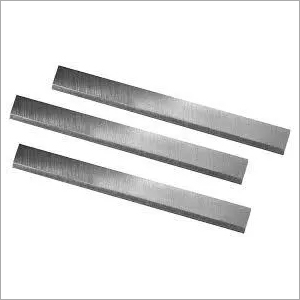

Veneer Peeling Knives

Veneer Peeling Knives Specification

- Shape

- Straight Edge

- Surface Treatment

- Polished

- Precision

- High Precision

- Design

- Rectangular Blade

- Type

- Veneer Peeling Knife

- Blade Material

- High Speed Steel / Alloy Steel

- Application

- Wood Veneer Peeling Machine

- Hardness

- 58-62 HRC

- Thickness

- 3-12 mm

- Sharpness

- Razor Sharp

- Edge Trimming

- Fine Edge Trimming

- Finish

- Mirror Finish

- Blade Edge

- Single Side Bevel

- Temperature Resistance

- Upto 300C

- Compatible Machine

- Veneer Lathe & Peeling Machines

- Usage

- Industrial Wood Processing

- Corrosion Resistance

- Yes

- Length

- 1000 mm 4000 mm

- Width

- 100 mm 220 mm

Veneer Peeling Knives Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

About Veneer Peeling Knives

Provided Veneer and Wood Peeling Knives are well admired among clients owing to their sharpness, longer life, rust-resistant surface, excellent strength and user-friendly design. With latest innovative techniques, offered knives are manufactured by our skilled professionals at ultra-modern production unit. These knives are ideal for cutting of wood in accurate shape and design. Provided knives are demanded in woodworking and furniture industries. Offered knives are safely packed for preventing damage during transit. In addition to this, provided Veneer and Wood Peeling Knives are tested on different parameters before dispatching into market for ensuring flawlessness.

High-Precision Veneer Peeling Knives

Experience premium quality with our high-precision veneer peeling knives, expertly designed for demanding wood processing operations. Each blade features a single side bevel and fine edge trimming capability, ensuring smooth, accurate cuts in every cycle. The mirror finish and ergonomic rectangular design promote longevity and ease of handling.

Engineered for Industrial Durability

Our peeling knives are manufactured with high-speed or alloy steel, delivering optimal performance in tough environments. With corrosion and temperature resistance up to 300C and hardness ratings between 58 and 62 HRC, these blades provide unmatched durability and consistent sharpness for veneer lathes and peeling machines.

FAQs of Veneer Peeling Knives:

Q: How are these veneer peeling knives used in industrial wood processing?

A: These veneer peeling knives are mounted onto veneer lathes and peeling machines to slice thin layers, or veneers, from logs. Their razor-sharp single side bevel ensures clean and precise cuts, making them ideal for high-volume wood processing operations.Q: What benefits do high-speed or alloy steel materials offer for these blades?

A: Blades crafted from high-speed or alloy steel provide exceptional hardness, increased durability, and superior resistance to corrosion and heat, which ensures the knives withstand intense industrial use while delivering consistently sharp performance.Q: When should I replace or re-sharpen my veneer peeling knife?

A: You should replace or re-sharpen your knife when you notice reduced sharpness, visible edge wear, or decreased cutting quality. Regular maintenance will preserve edge precision and extend the lifespan of your blades.Q: Where can I use these knives, and what machines are they compatible with?

A: Our veneer peeling knives are suitable for industrial settings and are compatible with wood veneer peeling machines and veneer lathes, making them ideal for wood product manufacturers and woodworking plants.Q: What is the process for installing these knives on veneer lathes?

A: To install, securely mount the knife onto the compatible lathe or peeling machine, ensuring the single side bevel aligns correctly with the log feed. Follow all safety and machine-specific instructions for a proper and stable fit.Q: How does the mirror finish and surface treatment benefit the blades performance?

A: A mirror finish and advanced surface treatments minimize friction during the peeling process, reduce material buildup on the blade, and ensure smoother cutting, which enhances both the knifes lifespan and the quality of the wood veneer produced.

Price 2000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

Aditya Enterprises

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |