Most Popular Products

|

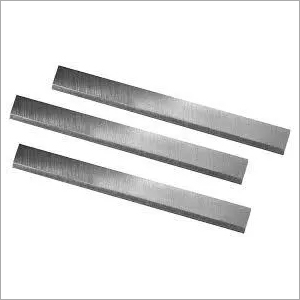

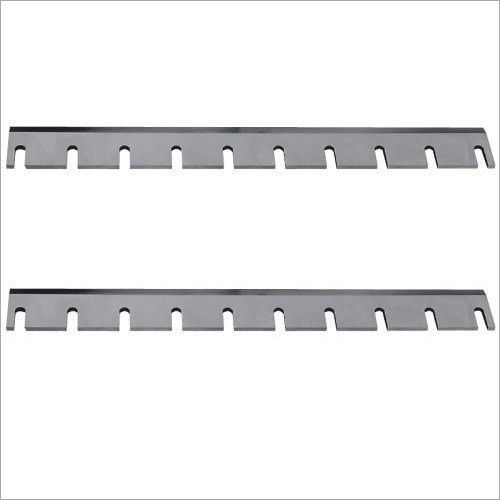

SS Veneer Peeling Knives

SS Veneer Peeling Knives Specification

- Precision

- High tolerance machining

- Shape

- Rectangular strip with straight edge

- Surface Treatment

- Polished

- Design

- Rectangular, flat-edge, industrial profile

- Type

- Veneer Peeling Knife

- Blade Material

- Premium stainless steel

- Handle Material

- No handle (blade only)

- Application

- Veneer and plywood manufacturing

- Hardness

- 58-60 HRC

- Thickness

- 3-8 mm

- Sharpness

- Razor sharp edge

- Edge Trimming

- Straight smooth edge for precision peeling

- Finish

- Mirror or satin finish

- Suitable Wood Type

- Softwood and hardwood logs

- Product Code

- SS-VPK-4637

- Edge Angle

- 27-36 degrees

- Heat Treatment

- Vacuum heat-treated for durability

- Cutting Efficiency

- Optimized for continuous industrial use

- Corrosion Resistance

- Excellent

- Width

- 100-200 mm

- Packaging

- Wooden box or protective wrapping

- Usage

- Automatic and manual veneer peeling machines

- Length

- Up to 1500 mm

SS Veneer Peeling Knives Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

About SS Veneer Peeling Knives

As the peeling videos of vegetables seem satisfying, our SS Veneer Peeling Knives are also satisfactory for numerous industrial peeling machines. These are designed with small orifices for the customers to insert screws, bolts and fasteners for complete and safe installation. They are smaller segments of different food machines yet work best for tough peeling purposes. These are structured with steel of stainless, carbon and mild grade to make them last longer as compared with different cutting and peeling components. The provided SS Veneer Peeling Knives are designed in semi-circular layout to enable fast and safe peeling while inducing less ingredient wastage.

Engineered for Industrial Precision

Our SS Veneer Peeling Knives deliver top-tier performance with high tolerance machining and a razor-sharp, smooth edge. Manufactured from premium stainless steel and subjected to vacuum heat treatment, they offer exceptional hardness and long-term reliability even under demanding operation. These knives ensure clean, precise cuts for consistent veneer thickness, maximizing yield and quality in production environments.

Versatile Application and Compatibility

Designed for use in both automatic and manual veneer peeling machines, these knives seamlessly handle the demands of processing softwood and hardwood logs. Available in lengths up to 1500 mm and widths ranging from 100 to 200 mm, they are adaptable to various equipment configurations. Mirror or satin finishes enhance their surface durability and provide effortless maintenance.

Safe Handling and Protective Packaging

Each blade is supplied in a robust wooden box or protective wrapping to prevent damage during storage and transit. Their flat-edge, rectangular profile makes installation straightforward. With no handle, these blades focus on delivering an uncompromised cutting surface for professional use in veneer and plywood manufacturing facilities.

FAQs of SS Veneer Peeling Knives:

Q: How are SS Veneer Peeling Knives manufactured for industrial durability?

A: SS Veneer Peeling Knives are fabricated from premium stainless steel and undergo vacuum heat treatment, which results in a hardness of 58-60 HRC. High tolerance machining ensures precise dimensions and uniformity, while surface treatments like polishing deliver both appearance and corrosion resistance.Q: What types of wood can these veneer peeling knives be used with?

A: These knives are engineered to efficiently peel both softwood and hardwood logs. Their razor-sharp edge and specific angle enable them to cut cleanly through a wide variety of wood textures commonly processed in veneer and plywood production.Q: Where can I use these knives and on which machines are they compatible?

A: SS Veneer Peeling Knives are suitable for use in both automatic and manual veneer peeling machines within veneer and plywood manufacturing settings. Their design accommodates a range of machine types and industrial applications.Q: What are the benefits of the high precision and edge angle design?

A: The high-precision machining and edge angle of 27-36 degrees provides a consistent, smooth edge that promotes uniform veneer thickness, reduces waste, and ensures excellent cutting efficiencyeven during prolonged continuous use.Q: How are the knives packaged to ensure they remain in optimal condition?

A: Each knife is packed in either a sturdy wooden box or suitable protective wrapping. This packaging safeguards the blades against physical damage and corrosion during storage and shipment.Q: What is the recommended process for using and maintaining these knives?

A: Install the knives carefully in your veneer peeling machine, aligning them according to your equipments specifications. Regular inspection and cleaning, combined with timely re-sharpening, optimize longevity and ensure the knives maintain their razor-sharp performance.

Price 2000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Peeling Knife Category

Veneer Peeling Knives

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Finish : Smooth Mirror Finish

Sharpness : Extremely Sharp Edge

Precision : High Tolerance

Application : Veneer Peeling, Wood Processing

Stainless Steel Peeling Knives

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Finish : Mirror Finish

Sharpness : Razor Sharp

Precision : High Precision

Application : Vegetable and Fruit Peeling

|

Aditya Enterprises

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |